Engine swaps are as common as donut shops these days. It seems as if everybody with an early model car or truck is dropping in an LS V8 to give their ride more power. But what happens to that power after it exits the engine’s crankshaft? If you are still using an early model transmission, you are not taking advantage of the extra juice you’re getting out of that new powerplant.

That was basically the situation Griffin Wayne was in with his gorgeous 1972 Chevrolet Blazer. This well-restored Blazer, powered by a built Chevy 383 ci V8 stroker was backed up by a TH350, and therein lay the problem. The old-school transmission was good enough, but it wasn’t great at handling the power generated by the potent engine.

Our order for the swap included the TCI-preppped 4L80E trans, the TCI EZ-TCU, a TCI Outlaw shifter, and the TCI-supplied Advance Adapters transfer case input shaft to adapt the 4L80E to the Blazer’s NP205 transfer case. All the necessary hardware and wiring was included.

Swap Meet

We had given the engine even more oomph by swapping out the carb for a Holley Terminator EFI 4 Throttle Body Fuel Injection setup. However, the TH350 transmission had become the weak link in the powertrain system. As Scott Miller at TCI Automotive put it, “The TH350 can only handle so much. Turbo 350s are notorious, especially in four wheel drives, for taking out the rear sprag assembly.”

“When you pull the TH350 transmission down into low gear that sprag assembly is engaged, and those things tend to break out of the case.” Miller continued, “If you get stuck and you’re trying to rock it out or anything like that, the 4L80E is just so much more durable. You don’t have to worry about that kind of issue.”

The biggest advantage of the 4L80E swap is its strength and durability. – Scott Miller

The 4L80E’s ratios from First to Reverse are: 2.48, 1.48, 1.00, 0.75, and 2.07. They both have identical or nearly identical gears, except for the addition of a fourth “overdrive” gear in the 4L80E that allows for better highway fuel mileage due to lower engine speeds at the same road speed.

A handful of improvements and upgrades were made to the TCI-supplied 4L80E, and the TCI Saturday Night Special torque converter got furnace-brazed fins and turbine spline reinforcement.

Miller said, “The biggest advantage of the 4L80E swap is its strength and durability. The 4L80E is an overdrive transmission and is somewhat based on the GM Turbo 400. It’s a good strong unit to begin with, but when you combine its overdrive capability with its strength and durability compared to a Turbo 350, it’s like night and day. It’s a plus in any application.”

In addition to the TCI 4L80E being a lot beefier than TH350, it has been prepped with valve body modifications that increased its cooling ability and improved shift characteristics. In other words, it won’t heat up as easily, and it has snappier, crisper shifts, yet it’s not as harsh as a racing style transmission.

The NP205 and TH350 were carefully removed (left) using our Bendpak transmission jacks. The necessary shortening (right) of the 4L80E output shaft was performed with a cut-off wheel. The cut and cleaned up transmission output shaft (below) is ready to accept the modified NP205.

Miller told us, “The 4L80E for that application is built around our Street Fighter specs. That basically means it gets the good aftermarket performance clutches, with extra clutches in all the clutch packs. It has the 34-element sprag assembly, and our valve body kit has been installed too. It also has the billet steel hub installed in it.”

“We do as much as we can to it without going up to the kind of modifications we do to the Super Street Fighter, with Red Eagle clutches, the aftermarket input shafts, and stuff like that.” Miller continued, “In this particular application that would be overkill.”

Easy Job

Swapping the 4L80E from TCI for the Blazer’s TH350 was fairly easy. The nice thing about the GM engines and the TCI transmissions meant for them is that they bolt right up with no adapters needed. The key here is to consult with tech reps at TCI when you’re getting ready to order so they know exactly what you’re doing, and can get you just the right transmission setup.

The Advance Adapters replacement 35-spline female gear from TCI must be implanted inside the NP205 transfer case.

The toughest part of pulling out the TH350 and hooking up the 4L80E was making sure we didn’t drop one on our toes while doing the job. Luckily for us, we had a couple of BendPak transmission jacks to help lift and steady the big chunk of metal while we were working.

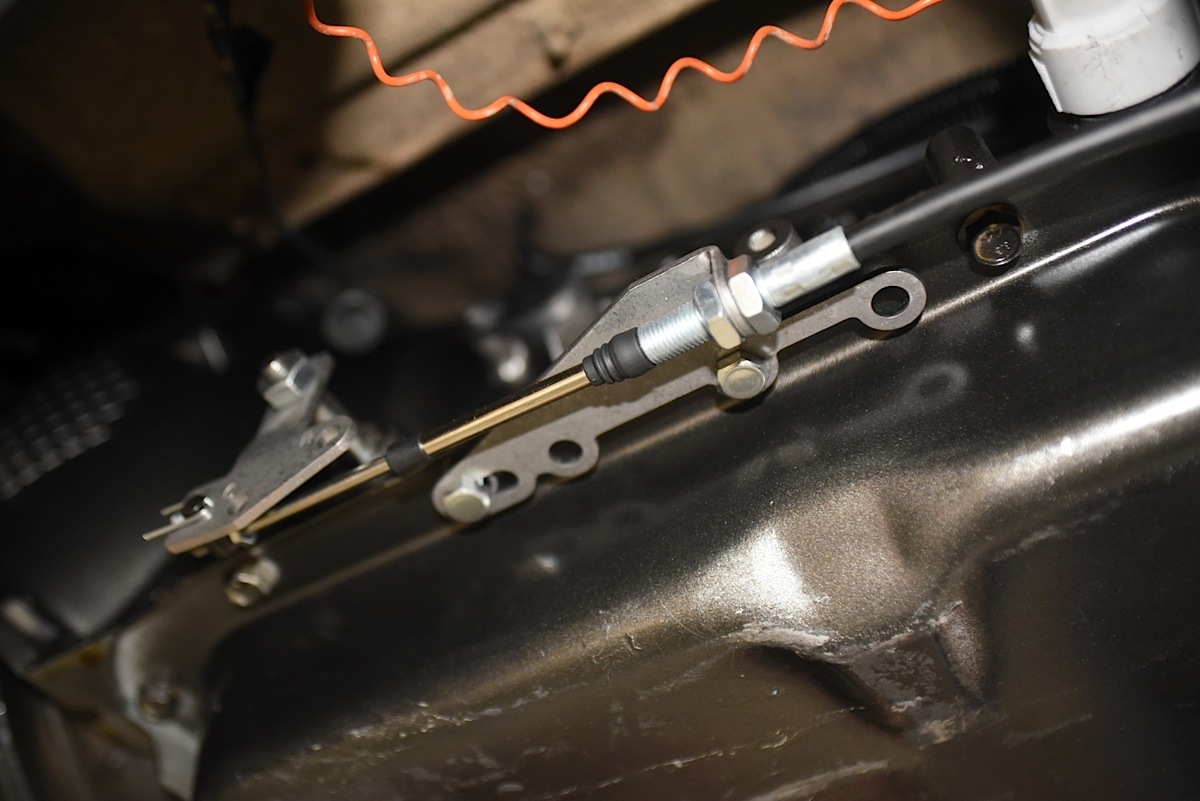

The electronic harnesses are plug-and-play, and the new shifter cable and bracket were a breeze to install. Flexible heat shielding is a part of the kit and was used to encase the cable and bracket where they meet.

The 4L80E for our 1972 Blazer came equipped with TCI’s Saturday Night Special Converter (No. 242900). Chief among the features that made this TCI torque converter such a bonus for our application were furnace-brazed fins and turbine spline reinforcement welds for greater strength and durability.

What’s more, a heat-treated steel hub that helps increase the overall strength of the converter is part of the package. The new converter also offered heat-treated sprag races that will handle more stress and have a longer life. Special bearings that help to reduce drag and increase the thrust capacity of the converter are also used.

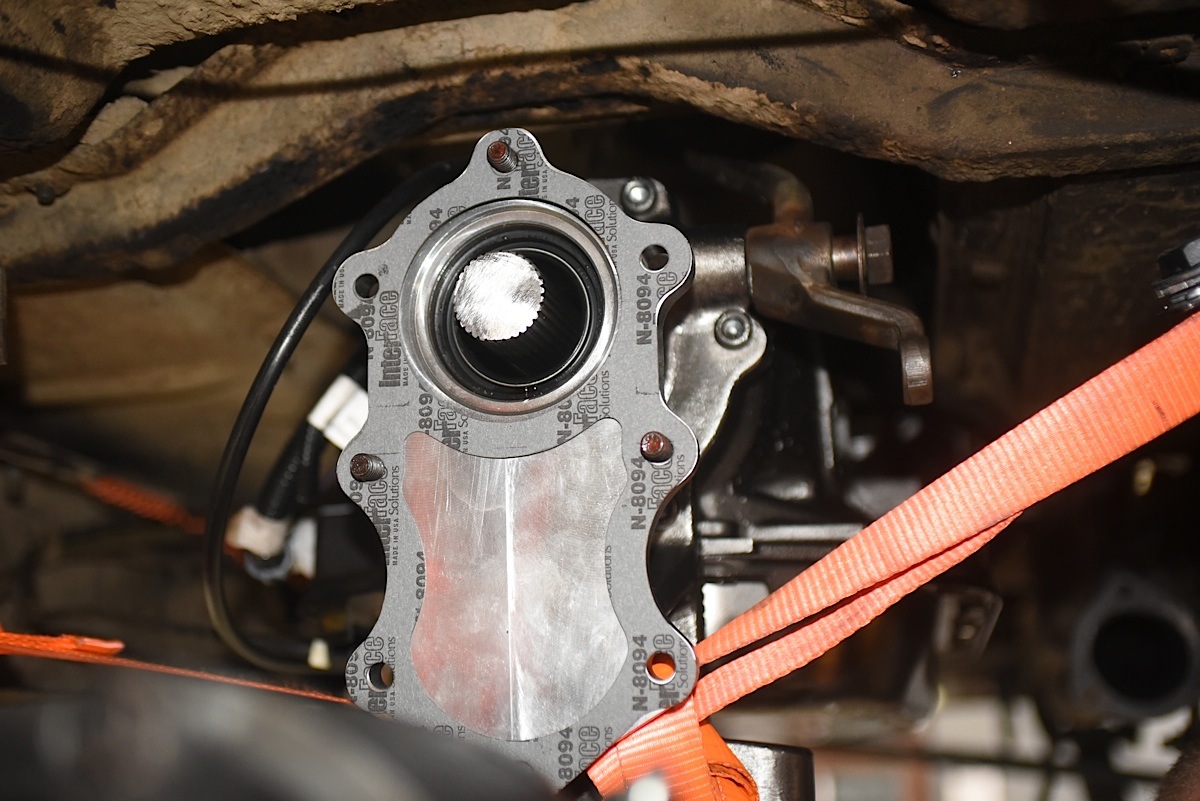

The old male input shaft (seen above in the NP205) gets replaced by the Advance Adapters 35-spline input shaft. With the new TCI 4L80E transmission in place and a gasket ready (lower left), the NP205 with its newly replaced input shaft (lower right) are ready to come together.

After TCI does all the mod work to the torque converter components, it is assembled and then the impeller is welded to the front cover. The company follows up with rigorous testing before the converter hits the street, too. Dial indicators on a rotating table are used to verify that the impeller body and pump drive hub are running true. Every converter is also pressurized and leak tested, and then computer balanced to eliminate drivetrain vibrations.

Electronic Control

Because the TCI 480LE is an electronically controlled transmission, it offers a huge advantage when it comes to drivability and smooth operation. It must be hooked up to and controlled by the TCI EZ-TCU by FAST Overdrive Transmission Controller (No. 302820). It is what offers the driver customized control over the shift points, shift firmness, and shift speed. The system allows users to program transmission calibration, and it’s capable of real-time switchable calibrations. So you could have programs for street, towing, and for off-road use, all in a single package.

The EZ-TCU package provides built-in diagnostics, and includes a transmission control unit, hand-held display, and a wiring harness. The great thing is this system is incredibly easy to install and use. We mounted our EZ-TCU underneath the Blazer’s dash near the center on the passenger side because there was plenty of room to place it in a location that was both tucked up and out of the way, yet it was still easily accessed for programming with the hand-held display and its wiring tether.

We tucked the TCI EZ-TCU transmission control unit under the passenger-side dash next to the transmission tunnel for easy access when it came time for plugging in for programming.

The entire system was designed for enthusiasts who are not especially fond of fooling around with electronics and don’t want to have to use a laptop computer to program systems such as this. “With the TCU and the transmission everything is sort of tuned together initially for the TCU,” said Miller. “It makes it easier to install and get working, especially for the novice that may be scared to mess with the electronic stuff.”

“One of the best things about our EZ-TCU system is that it’s plug-and-play. It’s so simple to set up that it’s almost dummy proof. You answer a few basic questions on the gearing and the tires, it then gets the RPM signal, and boom you’re on the road. The only time you have to break out the handheld again is if you want to adjust any settings.”

Shifty Business

For shifting duties, we knew that the stock steering column-mounted shift lever would have to go, but TCI had the answer. Its Outlaw Shifter was a perfect choice for the 4L80E because of its electronically controlled automatic shifting characteristics and its manual shifting option.

Our Bendpak transmission jack came in handy again, helping us hoist and position the NP205 transfer case for assembly to the TCI 4L80E.

The TCI Outlaw shifter handle featured an integrated two-button design to help improve shifting. It also eliminated the need to run wires to the steering wheel or a custom steering wheel for a paddle shifter. The shifter buttons mean instant engagement, and better gear transitions. The contoured handle is also very comfortable. The best part is that the Outlaw was easy to install, and included the cover, cable, and all hardware needed for proper installation.

For our application, installation entailed creating a custom sheet metal stand here in the shop for the Outlaw. That way the sifter would be high enough off of the floor to make the handle easy to reach from the driver’s seat without leaning over or forward. It’s nice to have your own shop with a sheer and brake, but any decent machine shop or sheet metal man could do the same for you. Holes were drilled in the floor atop the trans tunnel to accommodate the mounting of this custom stand for the Outlaw shifter.

The TCI Outlaw shifter cover is made from steel and powdercoated in crinkle-pattern black, and not only neatly hides and protects the shifter mechanism, but also the electrical and cable connections. It also offered two mounting holes for toggle switches on the driver’s side. Those toggle switches were used to control changing from Economy to Performance mode and from Automatic to Manual mode in the Outlaw’s shifting programs.

Miller said, “The shifter is a two-button handle type shifter and the buttons hook up to the harness on the TCU. All the wires are marked on the harness so it’s easy to install. One button upshifts a gear, the other downshifts a gear.”

The stock transmission crossmember was re-used, but due to the additional length of the new TCI 4L80E, it had to be relocated 3.5 inches rearward with new mounting holes drilled in the frame rails.

“There’s another wire that turns on and off the manual option. That gets hooked up to one of the toggle switches. The other toggle switch is wired to control switching between performance and economy mode. If you run it in the highway economy mode, it has a firm shift, nothing too harsh, but it’s sure and swift. The performance mode gives it a little bit firmer shift and a higher shift point.”

Miller explained, “Once you’ve used the TCU to set the shift tunes on the transmission, the second switch allows you to go back and forth between the two preset shifting programs. The manual option puts the transmission in gear select. You engage the gear select mode by putting the shifter in the fourth gear position and then turning on the manual option. Then the buttons provide electronically instantaneous shifts. However, if you’re in fourth gear in manual mode when you stop, you have to manually downshift because it’s operating as a true full manual.”

Our in-house fab shop created the custom stand (above) for the TCI Outlaw shifter. The side switches on the Outlaw were labeled (lower left) during the assembly process to make wiring easier. Holes were drilled in the floor, and then the Outlaw shifter and its custom riser stand were bolted (lower right) into place and all hooked up.

Adapting To The Times

Because the late-model, electronically controlled 4L80E transmission was being hooked up to an early-model NP203 transfer case, alterations and an adapter were needed to properly mate the two and make them work together. This was where the greatest work and alterations came in to play during the transmission swap. TCI supplied an adapter kit (No. 50-1410) from Advance Adapters for this purpose.

It included an adapter housing, new 32-internal spline input shaft, input gear bearing, gaskets, seal, fastening hardware, and instructions. The adapter also fit a factory GM transmission mount. The adapter assembly fits 1971-1979 GM NP205 transfer cases with a figure-8 front bolt pattern, and it’s designed to replace the 10- or 27-spline male inputs. If the GM NP205 is equipped with a 32-spline female input, the new 32-spline input included in the kit will not be needed.

The transmission shifter brackets and cable were installed (left), and then protected (right) with heat-resistant wrap.

First, the output shaft of the 4L80E automatic transmission had to be shortened. This is not something to be done lightly, as you do not want to mess this up. If you’re performing a swap similar to the one we were engaged in, and are uncomfortable with the task or don’t have the proper tools, our advice is to have a professional machine shop do the work. The output shaft must be cut to exactly 4.5 inches in length from the end of the transmission housing. Orin Euller at Advance Adapters told us, “The transmission is meant for a two-wheel drive truck, and if the output shaft is any longer, it will bottom out in the adapter’s new 32-spline input gear.”

When replacing a TH350 automatic or a four-speed manual transmission, the input bearing size on the NP205 must also be increased. The 32-spline input gear is a stock GM unit that was used on one-ton trucks only. That required the NP205 to be disassembled and machined to accept the adapter kit’s 32-spline input gear with its larger bearing size of 3.543 inches. Again, this is a job that, unless you have the tools and skills, is best left to a professional machine shop. Our tech’s have the skills, but not the proper machining apparatus in our shop, so this was sent out for work.

We had to reconfigure the stock transfer case shift lever, so it would reach back 3.5 inches to connect with the NP205 in its new position, and allow us to keep the lever in its original floor location.

The 4-inch thick adapter housing came bolted right to the back of the 4L80E, so that was no big deal. However, since the new transmission was longer than the TH350 it replaced, the original transmission crossmember could be reused, but needed to be moved rearward on the frame about 3.5 inches.

We bolted the crossmember up to the 4L80E once we had it mated to the NP205, and held the entire assembly in place with a transmission jack to know exactly where we needed to drill new mounting holes into the Blazer’s frame rails. Of course, movement of the transfer case position meant we needed new front and rear driveshafts. Careful measurements were made and then new shafts were procured. We also had to alter the shift lever to the NP205 transfer case.

Careful measurements (left) were made for the new replacement driveshafts. Once the driveshafts were in, we could do the custom work (right) needed to re-arrange the exhaust crossover system that would have interfered with the rear driveshaft in its new position.

One of the best things about our EZ-TCU system is that it’s plug-and-play. – Scott Miller

Because it was moved back with the longer 4L80E transmission, the NP205’s shift lever had to be bent to reach the transfer case’s linkage, and remain in its original trans tunnel hole location. It seemed that we were almost done.

All that was left was to fire it up, and do the programming through the hand-held interface to the TCI EZ-TCU unit. Once the TCI 4L80E was fully installed and ready to drive, we basically turned the hand-held programmer on, and then its Setup Wizard software walked us through the steps to get it set up. Now came time for some test drives.

The TCI EZ-ECU setup is easy to use. Once everything is installed and you are ready to run, you just turn it on and start answering a few questions. You can create custom optional programs, and get trouble codes through the system.

The system worked beautifully. We could feel the difference in shift control and firmness immediately, and it was lots of fun to work the Outlaw shifter and run the new 4L80E through its bases in the old Blazer. It made the 383 feel like a much larger engine too, as it seemed that the power came on quicker through the TCI 4L80E than it had with the TH350.

The owner could not have been happier. Wayne told us, “It’s made an amazing difference. When driving it conservatively, it feels like I’ve got a new Suburban or Tahoe! Smooth shifting all the way through. Throw a switch and you go from mild to wild, chirping the tires with precise shifts! This beast of a trans is quite the chameleon. It will adapt to whatever environment it’s put in.”

The owner of the 1972 Chevy Blazer expressed his satisfaction with the newly transplanted TCI 4L80E by romping around in the dirt for us.