Do you know the difference between a semi-float axle and a full-float rear axle? Knowing how they work and which one is right for a particular application is important to make sure you have fun on the trail. Currie Enterprises and Genright Off Road are here to help explain the differences.

On a semi float axle shaft, there’s a large flange with wheel studs pressed or threaded into it. The wheel bolts to this flange, and a bearing is pressed onto the axle shaft. This bearing effectively carries the weight on the vehicle. As the tire size and weight of the vehicle increases, the load on the bearing also increases.

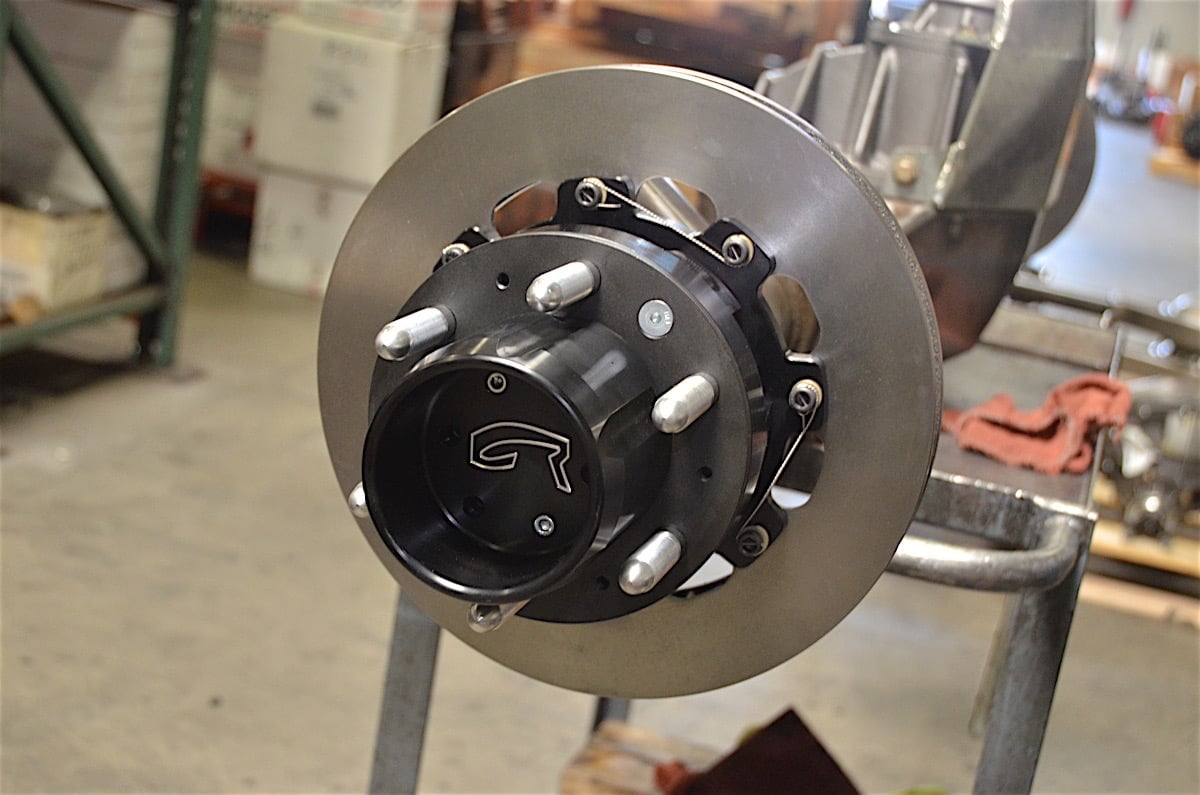

A full-float axle takes the weight of the vehicle off the axle shaft and puts it on the hub. The Currie full-float hub, in particular, allows for five, six, or eight lug pattern, plus it has a parking brake and tone-ring inside. This allows you to maintain your factory ABS and parking brake which is very important for a vehicle that sees any street usage.

In place of that single bearing are multiple bearings for increased load capacity. The hub on a full-float axle is completely independent of the axle shaft, one end of the axle shaft goes into the carrier and other into a drive flange mounted inside the hub. By putting the vehicle weight and drive force on the hub, a broken axle shaft won’t cause your wheel to fall off.

One of the benefits of upgrading to a full-float axle is larger axle shafts. Bigger is always better and when you’re running big tires you’ll need big axle shafts too. A full-float hub allows for up a 40-spline, or 1.75-inch axle. The Currie full-float hub allows you to keep your ABS and parking brake, while also providing the strength needing for big tires and big power.

For more information and to find the right axle for your rig, be sure to check out Currie’s website.