Building a built proof off-road vehicle is ideal to make sure that you can make it off the trail or back from the desert. For Project Storm Trooper it was time to look at the rear of the truck. With the long travel suspension up front, we need to look at how to make the rear of the truck stronger.

We turned to Currie Enterprises to help get the problem solved. We knew we wanted something that would be able to withstand the abuse off-road, and knew that meant only one thing, a Ford 9-inch.

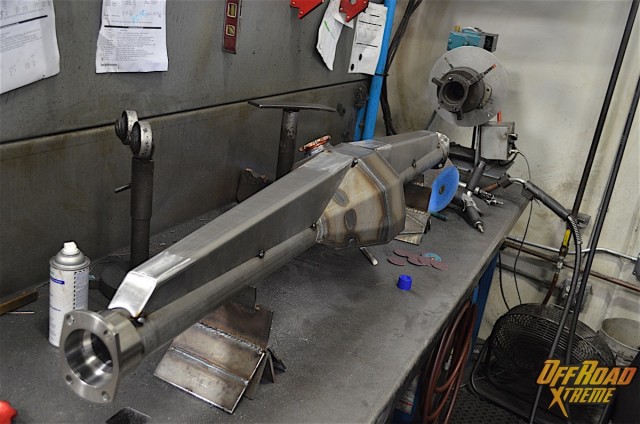

The beginning of the puzzle coming together.

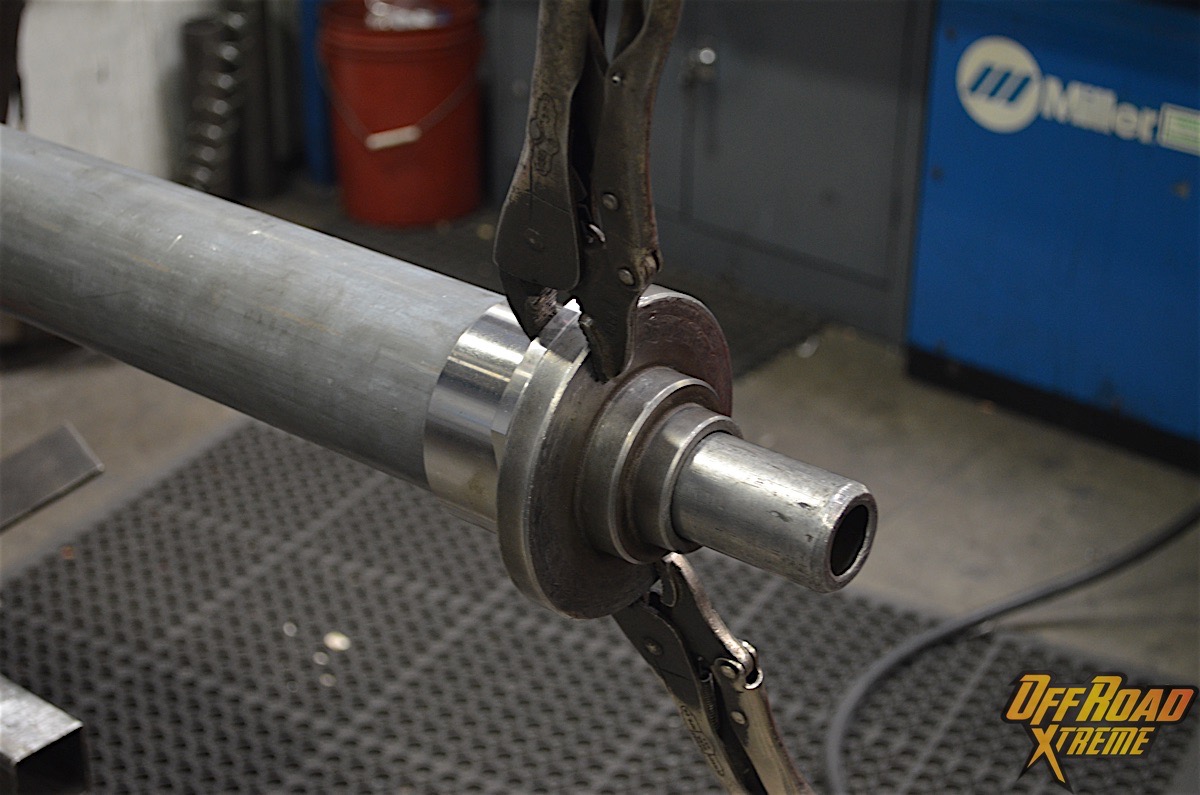

Speaking with Currie we were able to let them know our needs and the end goal of the build and ended up going with a Currie F9 fabricated housing. This housing features a unique center section design, with the first bend in the housing centered with the centerline of the axle tube.

The bend is the point of lowest ground clearance, and the flats on the housing provide maximum ground clearance at up to 20 degrees of pinion angle. Another unique feature is the welded in bulkheads inside the housing that tie the face, the body, and the inner ends of the tubes all together. According to Brian Shepard, “The F9 housing without the back brace is stronger by itself then a tradition 9-inch housing with the back bracing.”

We were able to watch all the pieces of the puzzle come together right in front of us. We will be mocking up the housing, tacking on spring pads and shock tabs, setting up pinion angle, and bringing it back to Currie to finish welding it all together.

Stay tuned for updates as we finish building the rearend of the truck, installing it, and going out and seeing what it can do.