When Murphy’s Law was written back in the late 1800s, off-road racing wasn’t even a flicker of an idea, and yet years later, we find out that this “law” is extremely applicable to the racing genre. Murphy’s Law reads, “anything that can go wrong, will go wrong” and it is all but completely accurate when describing off-road racing – a form of motorsports that will find any and all of the weak links in your race truck, guaranteed. While off-road racing continues to be the proving grounds for defining a vehicle’s structural merit, there are companies like Camburg Engineering of Huntington Beach, California, who are in the business of staying ahead of the curve by developing suspension and other components that will often outlive your truck.

When Murphy’s Law was written back in the late 1800s, off-road racing wasn’t even a flicker of an idea, and yet years later, we find out that this “law” is extremely applicable to the racing genre. Murphy’s Law reads, “anything that can go wrong, will go wrong” and it is all but completely accurate when describing off-road racing – a form of motorsports that will find any and all of the weak links in your race truck, guaranteed. While off-road racing continues to be the proving grounds for defining a vehicle’s structural merit, there are companies like Camburg Engineering of Huntington Beach, California, who are in the business of staying ahead of the curve by developing suspension and other components that will often outlive your truck.

Camburg Engineering began its rise to fame in 1997 and was started by two off-road enthusiasts, Jerry Zaiden and Jason Campbell. The goal was to engineer and manufacture suspension components for heavy off-road usage, which could not be found in the market at the time. What began from humble beginnings making parts for Toyota pickups has grown into a present-day footprint of a 10,000 square-foot shop that builds everything from A-arms to full race-bred KINETIK Trophy Trucks.

Camburg, which caters to a more enthusiast-focused sector of the off-road community that plans to use their trucks off-road, has built and designed some of the most sought-after suspension systems in existence. Over the past 18 years, Camburg’s products have been put on everything from daily-driven prerunners to purpose-built desert racing trucks, and can be found stocked in off-road shops across the country.

As fans of Camburg for over a decade and as fellow off-road enthusiasts, it was a dream come true when we were invited out to their Huntington Beach facility to speak with Zaiden, take a tour of their shop to see what’s new, and find out right from the source how the company came to be.

As fans of Camburg for over a decade and as fellow off-road enthusiasts, it was a dream come true when we were invited out to their Huntington Beach facility to speak with Zaiden, take a tour of their shop to see what’s new, and find out right from the source how the company came to be.

Off Road Xtreme: Hey Jerry, thanks for having us! Would you mind telling us a little about how you got into off-road trucks and fabrication in general?

Jerry Zaiden: “Absolutely. So me and Jason Campbell, before we started Camburg, were heavily into surfing and we got into shaping surfboards. That led me to making my first set of shaping racks, which were made out of metal square tubing. So, you know, being kind of the creative builder I am, I welded together my own set and that’s where I learned how to weld. Prior to that when I was in middle school, I went to Parker, Arizona, to the river with some friends and the house we stayed at was the owner of Ultra Wheels, Jim Smith, and he had a buggy in his garage. I went for a ride in the buggy and just kind of got bitten by the off-road bug!”

“At 16 years old, I had my first truck and wanted to basically put a suspension lift on it, but there weren’t a lot of people at the time that specialized in off-road Toyota suspensions. I went out to the desert and started using the truck to watch races like the Score Fireworks 250 Race, and just basically wanted better suspension that you just couldn’t buy from anyone. So, I wound up making some stuff in my garage and becoming more, I guess you can say, ‘auto enthusiast, but builder.'”

ORX: Did you have any jobs after building your own Toyota suspension system within the industry?

JZ: “Yes, taking the surfboard shaping, creativity, learning how to weld, and building my own parts, I got a job at Rod Millen Motorsports working with some of the industry’s best fabricators and working on a lot of rally cars – even Millen’s Pike’s Peak Celica which was a full tube chassis truck with giant turbos and a lot of horsepower! From there, I went off to work for a mountain bike company where I began making suspension seat posts.”

What started as a heavily Toyota-focused company has evolved into one that makes parts for all kinds of off-road trucks.

“I was making good money and was able to fix up my truck and began buying more and more tools. Jason (Campbell), my business partner, was working for BMP Fabrication in Costa Mesa, California, building race-quality mini-trucks and went to San Diego State University for an engineering degree. The owner of the mountain bike company basically wanted to take his company down a different direction than what I saw fit, so I hit up Campbell and was like, ‘We need to start Camburg, we need to start making parts that people can’t buy for their street trucks, but that are really racecar parts.'”

ORX: That’s quite a history! How did the early years of Camburg begin?

JZ: “So we started Camburg in 1997 basically with a small shop, a six-month lease, and some tools. It was a pretty simple thing. At the time, we were doing a lot of parts for friends, but then we got busy doing other stuff like Ford Ranger suspension kits. We started out as a Toyota-based company with Toyota pickup trucks but then the Ranger really took over, so I would say in a very short time, like less than a year or so, we really became a suspension staple to the prerunner movement. That kinda tied into our vision of making race truck parts available to the public. At the time, you had other companies that were doing basic lift kits and then some got really cheap with overseas parts, but we filled the niche with American-made racecar quality suspension components.”

“We like innovating and building really high-end products, but we’re also limited by the dollars people are willing to spend. Everyone cries and complains and wants the highest quality suspension built which would be TIG-welded, heat treated, whammy zammy stuff, right? But when you tell them that it’s $12,000 to $15,000 for a front kit, they don’t buy it. So that’s what’s been unique for us is seeing the needs of the customer and bringing a race-proven, high-quality suspension system to an affordable standpoint.”

“So while a full blown long-travel kit with billet hubs, big brakes, and uniball pivots that sells for $5,500 retail sounds expensive, when you really start adding up the cost of all the hard parts associated with the kit, it’s a really good value for what someone’s getting, especially since they know their kit has raced in Baja, the Mint 400, Vegas to Reno, or some other desert race. It’s very nice to have.”

ORX: How has Camburg evolved over the years?

JZ: “With seeing the customer’s needs, we’ve been able to grow and get more business which has let us invest back into our company with tools. We’ve now added a full CNC machine shop with a full CAD department, so now we do in-house CAD using SOLIDWORKS. This allows us to create a lot of other parts we didn’t think we would ever make when we started Camburg, because it was such a high-tech and expensive venture to do so. So when you look at the shop that’s got $500,000 worth of CNC machines, it’s not something you’re thinking about when you’re 23 years old and have no money, you know.”

In the early years, billet snouts made in-house were not possible. A true testament to the success Camburg has achieved.

ORX: What’s different about the off-road industry today compared to when you started out in 1997?

JZ: “I would say it’s relatively similar. You know, things have become more high-tech, like trucks are now coming with stability control and ABS brakes that are standard on everything. From other standpoints, the trucks now also lend themselves very well to being modified. So for instance, back then, to put coil-overs on the truck was a heavy fabrication venture. Now every vehicle comes OEM with a really short and small coil-over. So now we’re able to put longer coil-overs in their place with uniball upper A-arms or bolt-on long-travel kits. So in a sense, things have become a lot more bolt-on.”

“The other thing I’d say is different about it is you get lift kit companies building fake long travel kits, so it’s an uneducated public learning the hard way about the differences of suspension systems. Just because our system and the competition’s system have uniballs and are wider than stock, doesn’t mean they are the same. Big companies with big marketing dollars wind up putting stuff on their trucks that make the truck look cool, but it’s not quite the same thing. It’s really far from it and the stuff couldn’t be raced without breaking.”

ORX: What role has racing played for Camburg over the years?

JZ: “Racing for Camburg has been there since day one! We build our parts so they can handle desert racing; that’s how we compare our quality to our competition. Racing is how we’ve learned – not just selling a racer parts, but being involved with the racer and getting feedback to improve them. Now that we are building our full unlimited trick trucks, Trophy Trucks, and these unlimited vehicles, it’s always been a dream of ours to own one and race one. We kind of figured we would build our own, but never really looked at it that way. Now we’re like a staple in the industry – we’re one of the go-to sources on the highest-end level building these trucks.”

ORX: What has been your proudest moment in the history of Camburg?

JZ: “The proudest moment in the history of Camburg – I don’t know, it’s weird, like it doesn’t really feel like we look at it that way. Sometimes, when the race truck gets all put back together and there’s a few radical vehicles in the shop, you step back and look at it and go, ‘you know, there’s three of these $280,000-$300,000 race trucks all parked next to each other in the shop.”

“That’s a million dollars of race vehicles that we’ve made. It’s kind of one of those things that makes us proud because we are hand building vehicles that are the same price as a Rolls-Royce. So when you look at Ferrari, Rolls-Royce, or any of these high-end companies, we’re essentially doing that, and that is a humbling yet exciting feeling. It’s a proud moment creating these ultimate vehicles.”

ORX: Describe the type of enthusiast you market Camburg products to. Who is your core market?

JZ: “Basically, the enthusiasts we market to are just true people who are really into the off-road movement. They really want to use their vehicle and it’s not just a street truck. That’s why we’re three buildings tucked back away in an industrial park; we don’t rely on the drive-by, casual guy. We just want to build really cool high-end stuff for the real off-road enthusiast.”

Surrounded by built off-road trucks on all accessible corners, it’s obvious that what goes one behind these walls is real business.

ORX: What do you see as the overall health of the off-road industry right now?

JZ: “For us, 2014 was a record year by a long shot and it sounds like it was for a lot of companies we deal with. I feel like the off-road market’s doing really well. I don’t know how the lift kit market’s doing, but I know the off-road market. The guys that make good usable product, that customers are really going to enjoy off-road, are doing great.”

ORX: How has technology helped Camburg have yet another great year?

JZ: “Technology like SOLIDWORKS and CAD are enabling a lot of people to build really cool stuff. The difference is, we know you can’t just draw it in SOLIDWORKS, build it, and stick in on a vehicle. You still need to do it by hand. So our thing is that it’s ‘computer-aided’ drafting. We use it to get us close to start off with, and then we tweak and fine-tune it, then go back and test it. It’s easy to design kits with computers, and we see these new guys who come and make sure everyone knows who they are and then they fade away. The good guys stick around.”

ORX: Well we really appreciate your time Jerry. One final question: where do you see Camburg going over the next 10 years?

JZ: “Over the next 10 years, I see us getting more organized, growing, having more inventory, and building more race trucks. Basically, doing the same thing we are now, just on a larger scale.

Did I think Camburg would be where we are today when we started? Yes and no. Looking back, it feels the same to me, just bigger. It doesn’t feel like it’s really anything different than it was, but when you step back and look at it, it’s a pretty big moving ball, so to speak. Campbell and I were so young and we basically started with a welding machine, a cheap tubing bender, and then worked really hard and bought an iron worker and a cold saw, you know and just kept investing. We started with a couple grand each and it’s amazing to see what it’s become. I hope for the same over the next 10 years!” Well stocked with inventory already, Camburg hopes to have even more in the coming years.

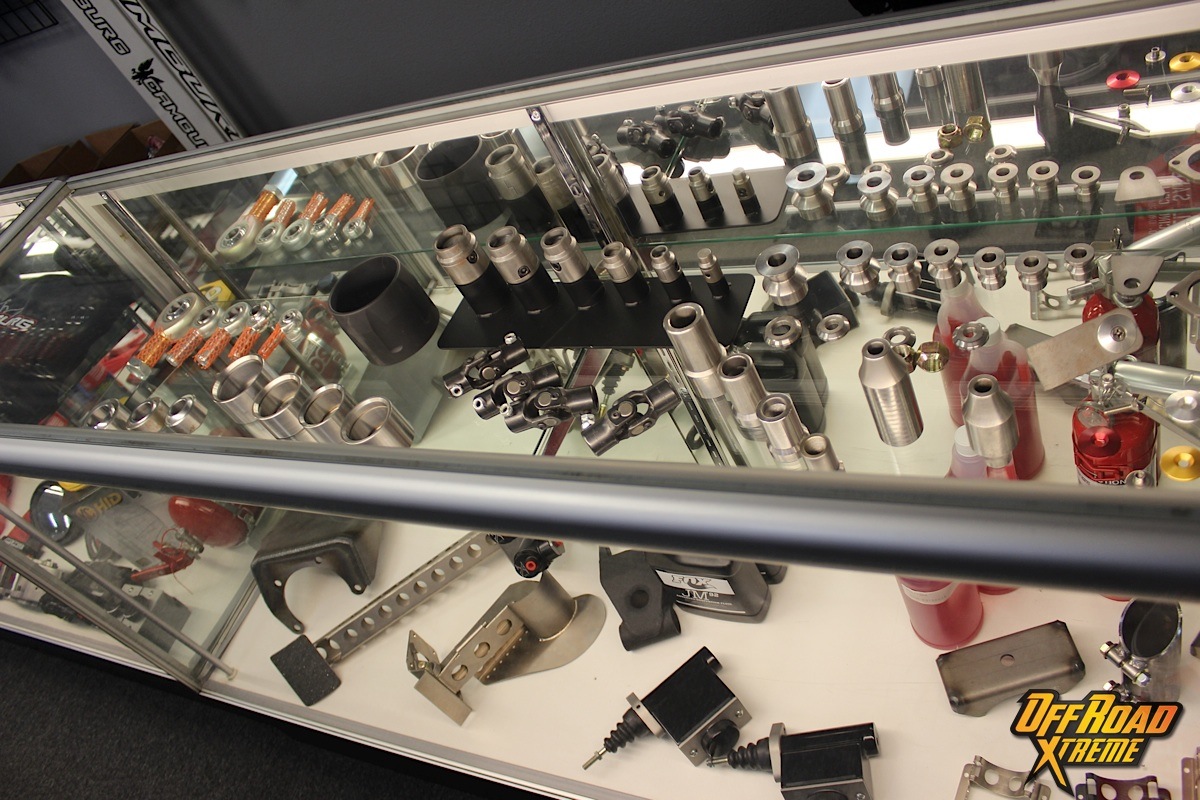

Getting to take a full tour of the Camburg facility really was a great experience, especially after following the company for so long. From the exterior, the humble shop that sits surrounded by desert-ready off-road trucks conceals the imaginative manufacturing that lies within the walls. The lobby that shows off some of Camburg’s most noteworthy kits and components serves as a gateway into the shop that houses a full manufacturing section, numerous high-end manufacturing machines, and a full spread of floorspace designated for building anything from a stock truck to the full-on KINETIK race trucks. The shop's lobby houses everything a racer or weekend warrior may need.

With roughly 18 full-time employees and their in-house ability to run the full cycle of a new component, from idea to finished product, Camburg Engineering has proven time and time again that they have what it takes to build some of the toughest off-road suspension systems on the market. Having a product catalog that offers parts for nearly all of today’s most off-road focused vehicles, there is a good chance that Camburg has the parts to take your off-roader to the next level and allow you to fully bring out the vehicle’s potential.

We here at Off Road Xtreme would like to personally thank Jerry Zaiden for the all-access pass to view the amazing facility, and if you’re in the market for some off-road components for your ride, you owe it to yourself to check out the Camburg homepage. For more from Camburg, including a full feature of the KINETIK line of race trucks, keep it locked on Off Road Xtreme!